Why Envacet?

Since 1990, Envacet has designed and supplied innovative engineered processing systems for the food industry. Envacet technologies assist our customers to achieve their sustainability objectives while delivering improved profitability.

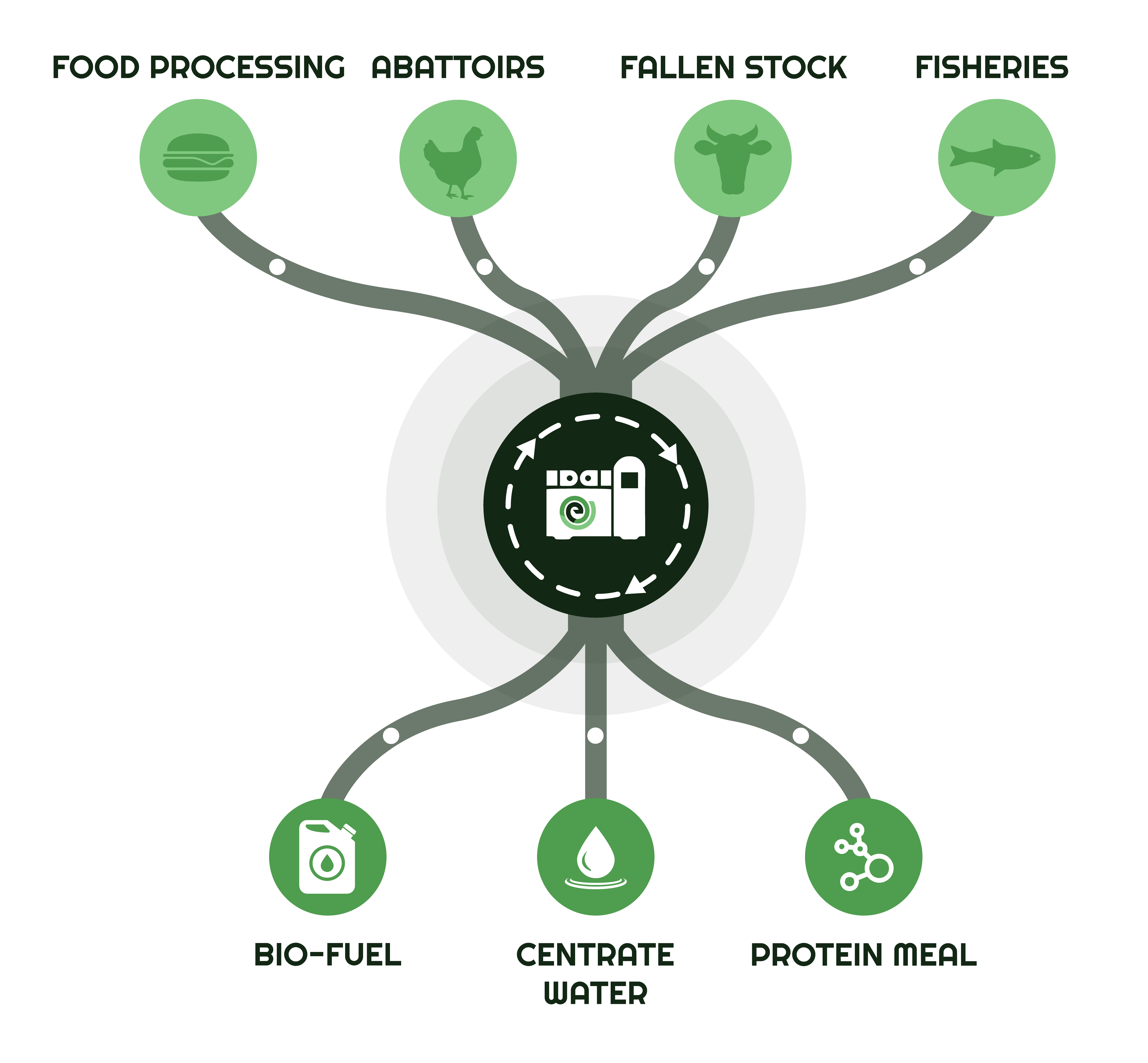

At the company’s core is its proprietary and proven Envacet Mechanical Centrifuge Extraction Technology (EMCET), a unique and cost-effective on-site processing system that converts organic material inputs into high-value products.

Envacet offers a range of purchase and operational options to ensure our customers can select the most appropriate solution – maximising the value of their by-products and enhancing the sustainability of their operations.

The EMCET Process

The EMCET process is a patented, cost-effective, on-site processing solution for a broad range of organic materials across many food-processing operations. It combines low-temperature material processing with a proprietary-designed separator that delivers unbeatable process efficiencies and premium quality outputs of oil and protein.

industries ENVACET works with

Abattoirs

Fisheries

Fallen Stock

Food Processing

Carbon Trust Report (2021)

In September 2021, the Carbon Trust published a case study on the impact of an Envacet project on the processing of fallen stock. The key findings were that the EMCET process delivered:

- A 75% reduction in electricity consumption vs. a typical processing plant using existing technology.

- A 40% reduction in thermal energy consumption.

- Further reductions in on-site carbon emissions can be achieved when linked to a combined heat and power (CHP) plant that utilises the oil recovered in the EMCET process.