Proprietary Technology Driving Innovative Service

Envacet’s Proprietary

EMCET Process

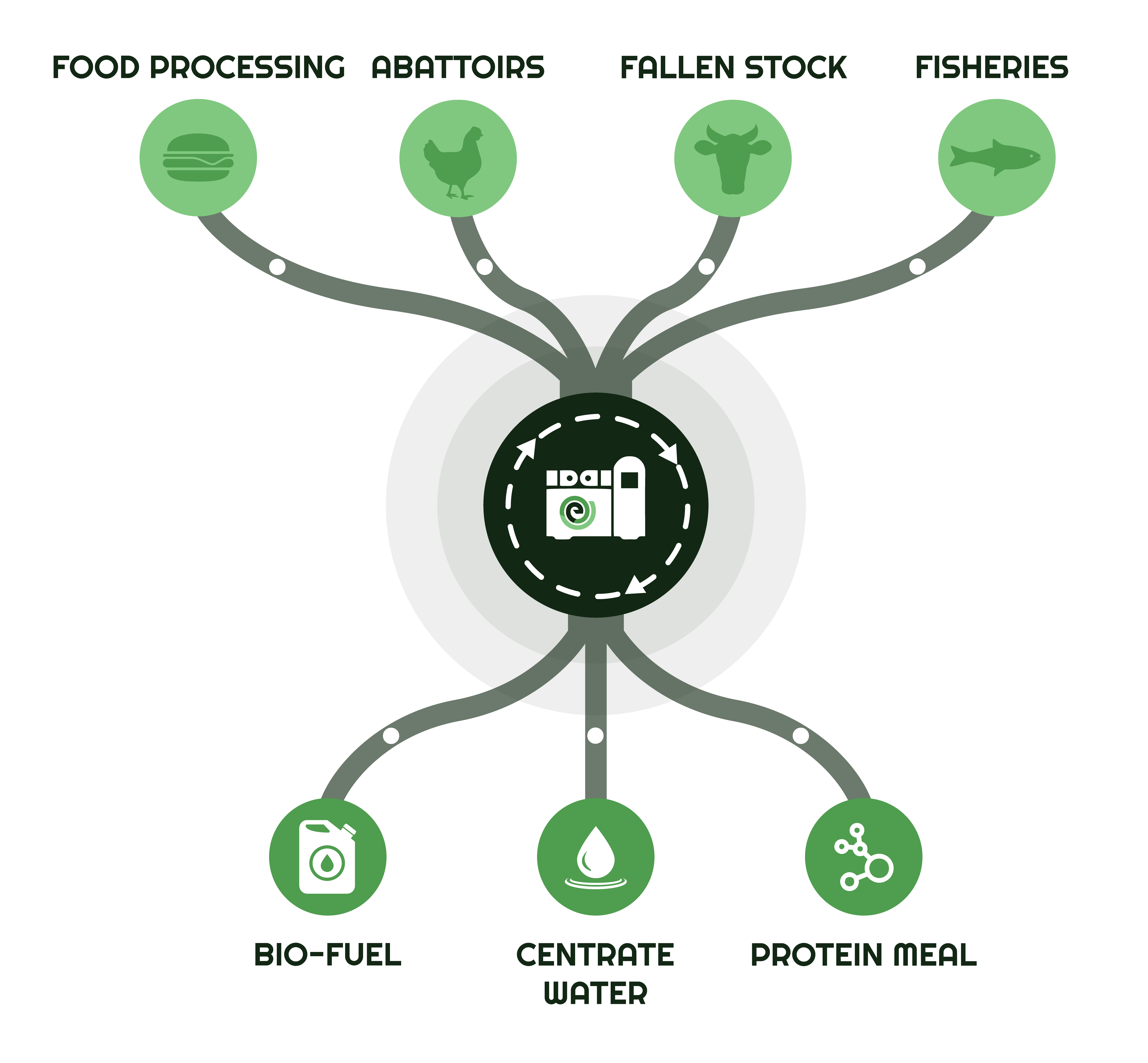

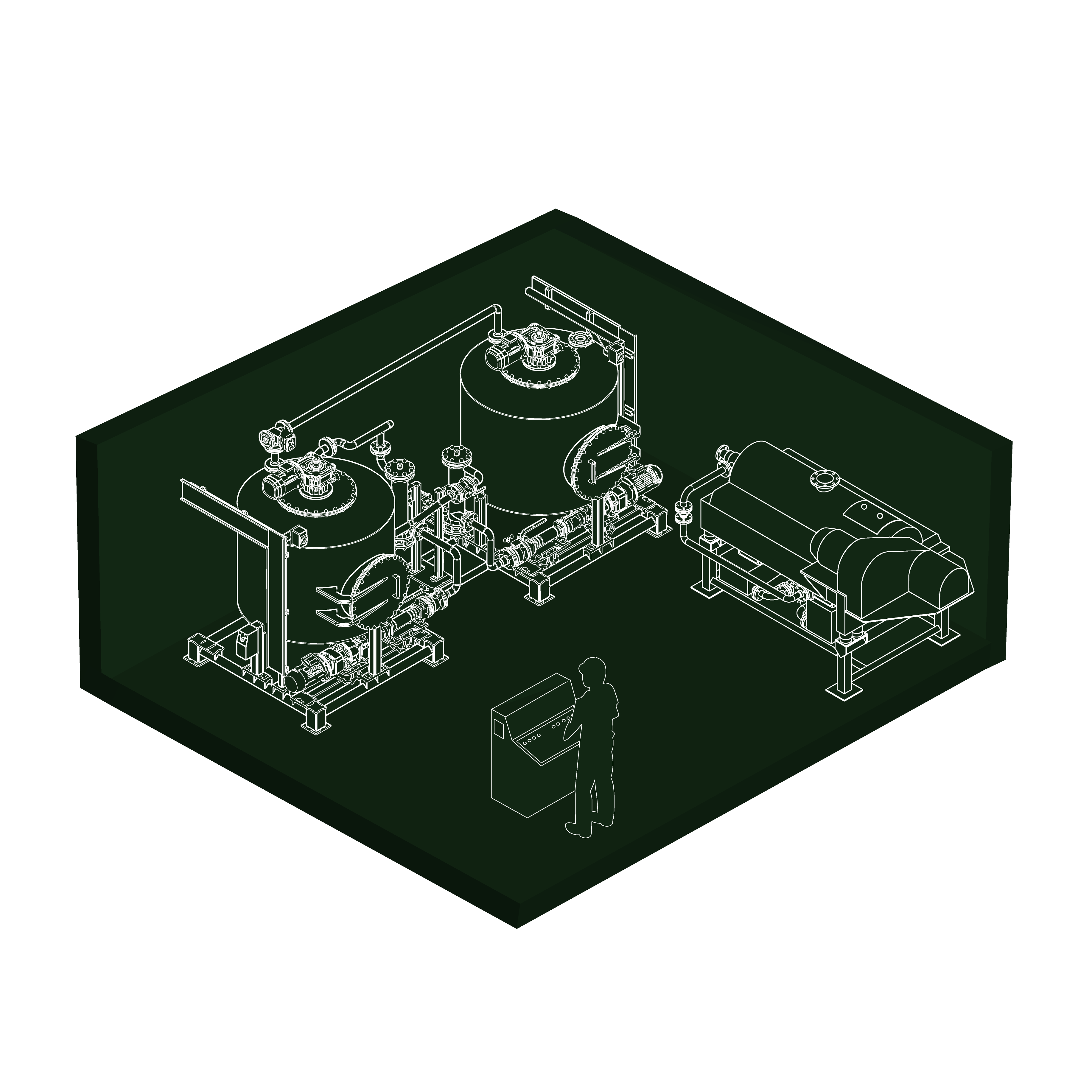

The EMCET process is a patented, cost-effective, on-site processing solution for a broad range of organic materials across many food-processing operations. It combines low-temperature material processing with a proprietary-designed separator that delivers unbeatable process efficiencies and premium quality outputs of oil and protein.

Material Pre-treatment, Separation, End Product Enhancement

Step One

Material Pre-treatment

Envacet can manage a broad range of organic waste streams. The waste material is pre-treated into a macerated slurry so it is suitable for the core EMCET process.

Step Two

Conditioning & Separation

The fully enclosed and patented EMCET process then conditions the material at temperatures below 100°C ready for the next stage. This ensures high levels of process efficiency (up to 75% more efficient than traditional methods) and no emissions. The conditioned organic slurry is separated in a proprietary design separator/centrifuge that delivers extremely ‘clean’ separation, hence the premium-priced outputs of oil and protein.

Step Three

End-Product Enhancement

The output products can be further refined to suit customers’ requirements. For example, proteins can be dried or chilled, while oil can be further refined for immediate combustion on-site to generate heat and power.

Integrated Renewable Energy Solutions

Envacet can integrate the EMCET process with a combined heat and power (CHP) unit or a dual-fired steam boiler to utilise the recovered oil directly on-site. With increasing focus on energy costs, energy security and carbon intensity, this can deliver a win-win-win for our clients’ operational energy strategies.

Envacet can offer a range of processing options to suit your needs

Scalable: EMCET is available in a range of sizes from 3 tonnes per hour upwards.

Input material range: Configurable and fully integratable with size reduction equipment to process a full range of organic inputs from whole carcasses down to fish trimmings.

Input material type: Capable of processing animal by-product Category 1, 2, or 3 material as well as organic material still fit for human consumption.

Output material conditioning: Available with output processing options to suit the size and type of animal by-products to be processed (eg. protein drying).

Approach to on-site integration: Can be built into an existing building or supplied skid-mounted in a shipping container to fit most sites.

Energy system integration: The EMCET process can also be integrated to run steam boilers or on-site CHP, providing electricity, hot water and steam that further enhances site sustainability.

Envacet’s Purchase and Operational Offering

If required, Envacet can offer fully funded purchasing options. We can provide a full range of services through the entire project lifecycle – from design through to operations, maintenance and output sales.

BUSINESS PLAN DEVELOPMENT

- Undertake analysis of existing material flows and costs

- Develop investment case

- Identify output market options

- Develop/provide funding solutions as appropriate

PROJECT DEVELOPMENT AND PLANNING

- Develop CAD drawings for on-site location

- Obtain requisite planning and permitting

- Manage local requirements of EA or APHA (or equivalent)

- Develop an on-site integration plan

PROJECT MANAGEMENT AND CONSTRUCTION

- Provide overall project management

- Fully manage on-site installation and commissioning

ONGOING OPERATIONS AND MANAGEMENT

- Provide and manage operational teams

- Provide full maintenance support (periodic and reactive)

- Remote monitoring and diagnostics

OUTPUT SALES AND MARKETING

- Develop and manage optimal markets for output materials

- Process material sales

- Manage output material logistics